Manufacturing

Manufacturing faces real challenges, from downtime to fragmented systems. Echovyn Labs offers industrial IT services, integrating OT with IT. We use Industrial IoT for real-time data, boosting efficiency and cutting costs. It's about making things work better, not just faster.

Overview

Navigating Modern Manufacturing's Digital Evolution

Manufacturing is undergoing a profound digital transformation, driven by Industry 4.0 and smart manufacturing principles. Technology, including Industrial IoT and AI, integrates operational and information systems, creating data-driven production environments. Investing now is crucial for future competitiveness.

Competitive pressures demand greater efficiency and agility in Manufacturing. Modern companies are adopting connected, automated, and data-driven operations to meet evolving market expectations for quality and speed. This shift highlights critical areas for operational improvement.

Key challenges we solved

Industrial companies face critical operational and technological hurdles. These challenges impact efficiency, limit growth, increase costs, and hinder competitiveness in a rapidly evolving market.

Manual Data Handling

Manual data entry and paper records slow production. This impacts efficiency and increases scrap rates.

Legacy System Limits

Outdated systems hinder growth and multi-site scalability. This limits expansion and responsiveness.

High Production Costs

Unplanned downtime and reactive maintenance raise costs. This reduces overall equipment effectiveness.

Outdated Factory Tech

Lack of real-time industrial IoT data limits visibility. This impacts decision-making and market agility.

Technology Solutions for Manufacturing

These solutions focus on integrating operational technology with information technology to create data-driven production environments for the Manufacturing industry.

This solution develops AI models capable of generating new content, insights, or intelligent interfaces based on existing data.

This involves creating intelligent knowledge retrieval systems for maintenance manuals and operational procedures. It also includes developing natural-language interfaces for querying production data and semantic search capabilities within PLM systems. The solution supports AI-powered quality inspection applications.

This solution implements and customizes enterprise resource planning systems to manage core business processes and resources.

This includes deploying and configuring ERP and Production Execution Systems (MES) for production planning, inventory, and shop-floor management. It provides modules for supply chain visibility, quality control, and financial operations. The service establishes a centralized platform for operational data.

This solution connects disparate systems and processes, establishing unified data flows and automated workflows across operational environments.

This includes implementing Industrial IoT for real-time data collection from machines and sensors. It also covers integrating custom and off-the-shelf systems for cohesive production planning and shop-floor management. Data engineering services establish standardized data models for advanced analytics.

This solution applies advanced algorithms to production data, enabling predictive capabilities and intelligent decision support systems.

Components include models for demand forecasting, quality prediction, and anomaly detection in production lines. It also provides asset health analytics for predictive maintenance and operational efficiency improvements. This supports data-driven insights for various manufacturing processes.

This solution verifies the functionality, performance, and security of software systems used in industrial and enterprise settings.

Services encompass functional, performance, and security testing for custom industrial software and integrated systems. This ensures reliability, data integrity, and compliance with industry standards. Deliverables include test plans, execution reports, and defect management for robust system operation.

Our Approach

We deliver industrial solutions with a predictable, collaborative approach, minimizing risk and ensuring operational continuity from concept to shop floor.

Diagnose

Architect

Integrate

Optimize

Why Choose Echovyn Labs?

Echovyn Labs?

Selecting the right technology partner is vital for industrial growth. Echovyn Labs provides practical, focused solutions that address complex operational needs.

Operational Value

Operational Value

Achieving higher operational efficiency and reducing production costs are constant priorities in manufacturing. Limited real-time visibility and frequent downtime often hinder these goals, impacting profitability and resource use across the production floor. Echovyn Labs helps clarify these complex areas.

We focus on integrating systems to provide clear data insights, helping you identify and resolve inefficiencies. Our approach to Automation & Integration helps connect disparate systems, creating a more cohesive and data-driven production environment for better decision-making.

Reliable Operations

Reliable Operations

Unplanned downtime and inconsistent asset reliability can significantly disrupt production schedules and increase maintenance expenses. Relying on reactive maintenance strategies often leads to higher scrap rates and missed production targets, impacting overall output and delivery commitments.

Echovyn Labs helps shift your operations towards proactive, condition-based maintenance. By applying advanced analytics and monitoring, we help predict potential equipment failures before they occur, contributing to more stable production and reduced unexpected costs.

Clear Visibility

Clear Visibility

Fragmented legacy systems and data silos often create a lack of end-to-end visibility across your supply chain and production lines. This disconnect hinders responsiveness, making it difficult to adapt to market changes or identify bottlenecks effectively within your operations.

We work to unify your data platforms, providing a single source of truth for better decision-making. Our ERP Services are designed to integrate core business processes, offering a clearer view of your entire operation from planning to delivery.

Practical Solutions

Practical Solutions

Many companies discuss broad industry trends, but the challenge lies in practical implementation that addresses specific operational hurdles. We focus on transforming abstract goals into concrete, actionable systems that deliver measurable results for your business.

Echovyn Labs approaches each project with a focus on tangible outcomes, understanding that mid-sized firms need solutions that provide immediate, clear value. We help translate your vision into implemented technology that works within your existing environment.

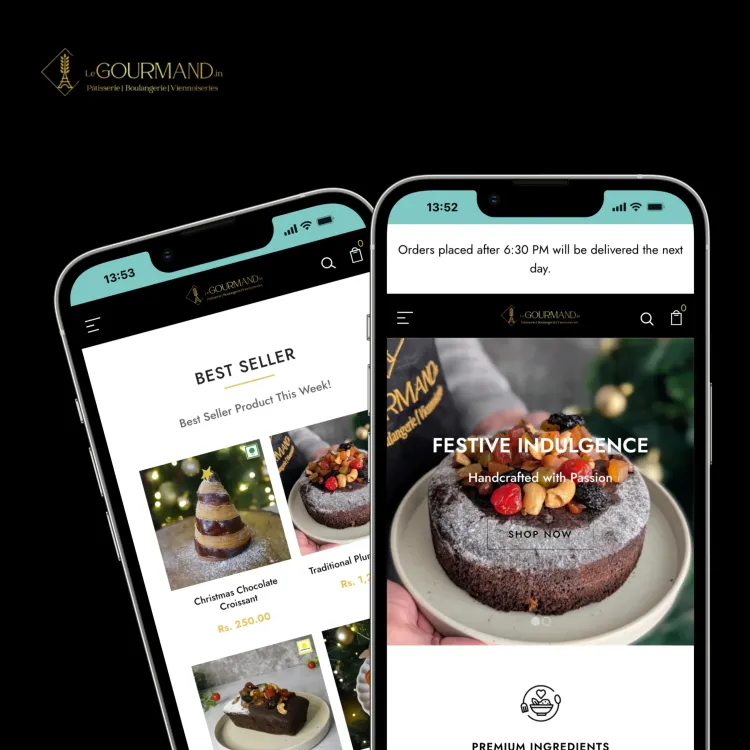

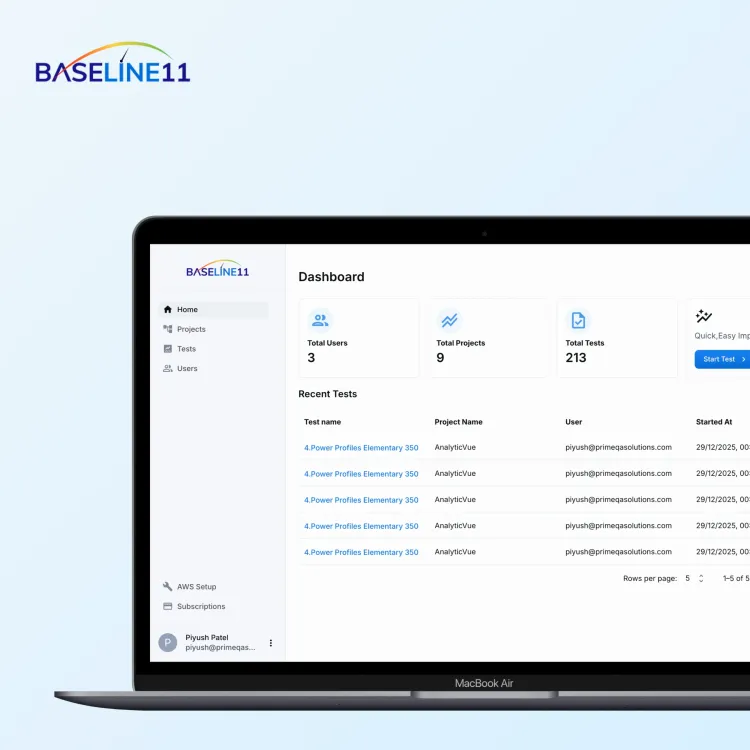

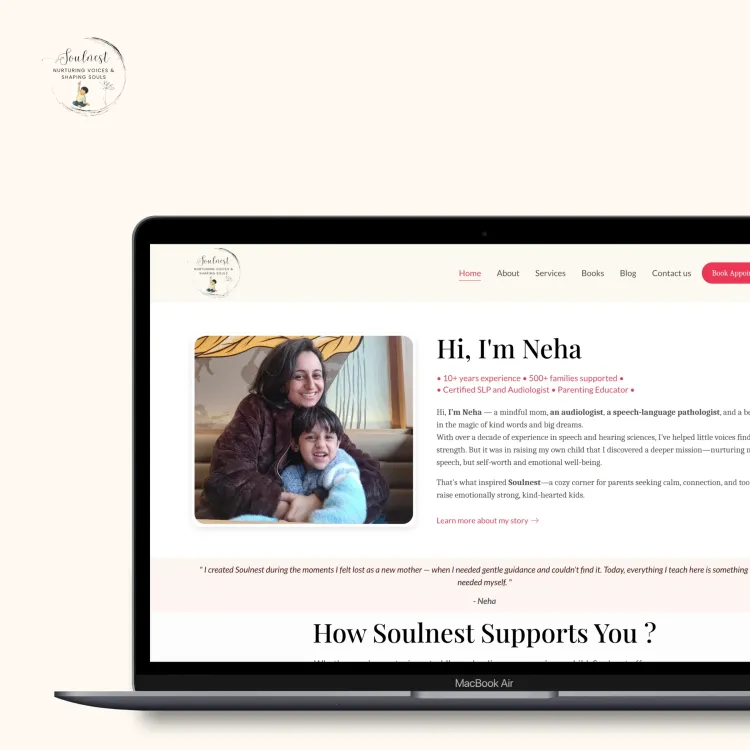

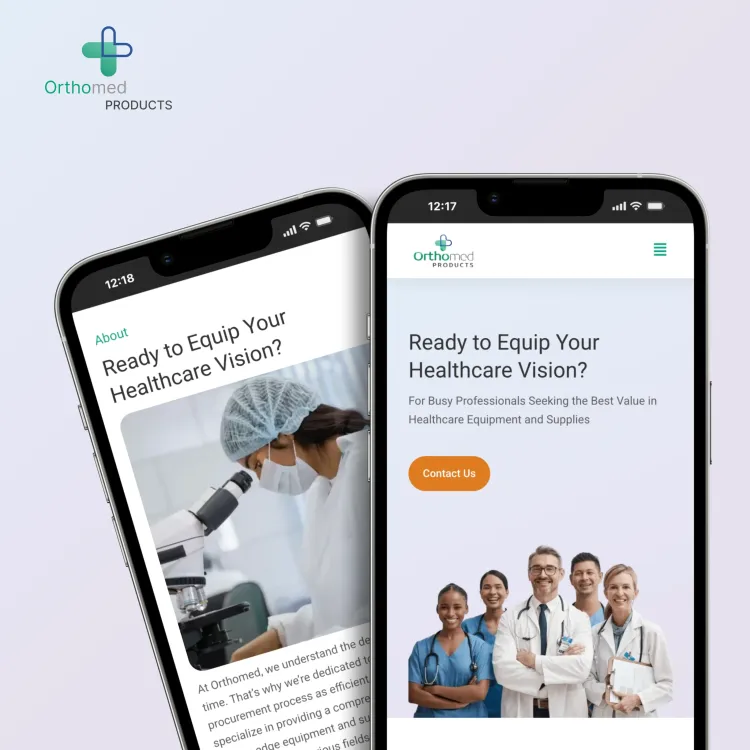

Case Studies

Real projects that solved real problems. See how we work with clients to create digital solutions that make a difference for their business.

Get in touch

Use this form to reach out with your requirements or questions. We take the time to understand your situation before suggesting any direction or follow-up.